Edward Masendo

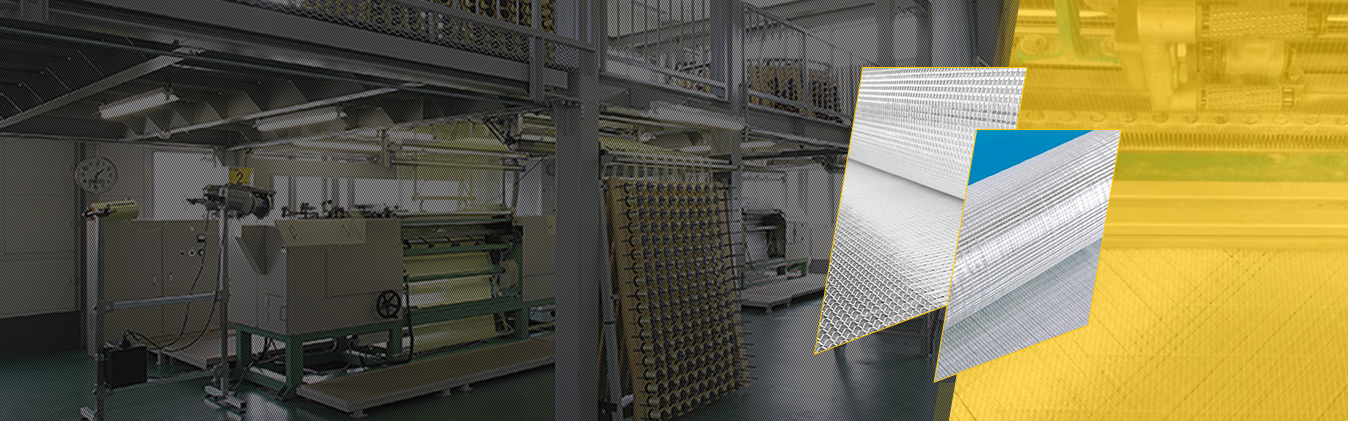

"Their technical team recommended a specific fiberglass axial cloth based on our filtration requirements and provided samples for rigorous testing in our filtration system, it exceeded our expectations in terms of filtration efficiency and improved our air filtration system performance."